Description

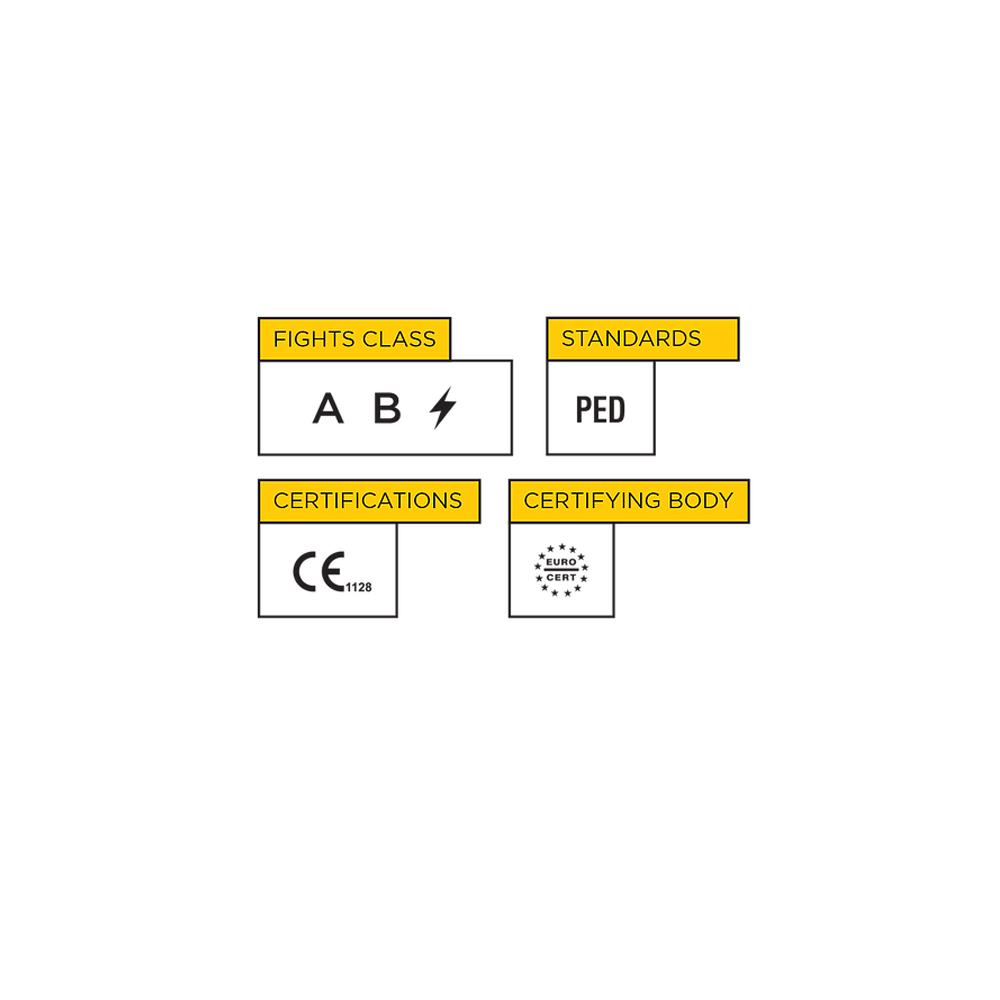

- Fights Class A, B and E class fires

- High firefighting effectiveness

- Ennvironment-friendly

- World’s most stringent quality standards

- Available in 10ltr & 50ltr

Product Overview

Water is fire’s oldest enemy. The best extinguishing agent known to man. It has a theoretical cooling ability of 2.6 MW per litre per second. But in a real fire situation, such tremendous cooling power can only be achieved with hundreds of litres of water. Because nearly 80% of the water escapes the fire zone without evaporating. Water’s immense firefighting power can be optimally utilised only by complete vaporisation in a fire environment.

To achieve this, water must be broken down into microscopic molecules that have a surface area coverage many times higher than water. These droplets (about 150 microns in size) must then be delivered to the fire with a kinetic force strong enough to overcome fire’s own convection currents. The result: a powerful, reliable and efficient extinguisher.

Ceasefire now brings together all these features and creates the Watermist Compressed Air Foam System; the best firefighting weapon ever designed. Ceasefire’s Watermist Compressed Air Foam System features a high technology gun which breaks water up into miniscule droplets. These droplets are then delivered through micro nozzles with a high degree of dispersion onto the flames, allowing you to fight even very large fires successfully.

With Ceasefire’s Watermist Compressed Air Foam System, nearly a 100% of the mist turns into steam and evaporates. This key process stops the fire from spreading and eliminates post fire collateral damage such as flooding.

The mist also acts as the perfect barrier against thermal radiation, giving increased protection to the firefighter. Ceasefire’s Watermist Compressed Air Foam System is also safe to use on Class B fires like petrol and diesel, and electrically started fires – two areas where traditional water applications would either spread the fire, or cause an electrical shock.

Product Features

Introduction: Water’s immense firefighting power is harnessed in CAFS Water Mist extinguishers by breaking it down into microscopic molecules. These droplets (about 150 microns in size) are delivered to the fire with a kinetic force strong enough to overcome fire’s own convection currents.

Works on large fires : The gun in Ceasefire’s Watermist Compressed Air Foam System features a rotating motor, which breaks water up into miniscule droplets. These droplets are then delivered through micro nozzles with a high degree of dispersion onto the flames, allowing you to fight even very large fires successfully.

Increased protection : The mist also acts as the perfect barrier against thermal radiation.

Application: Works on Class A, B and electrically started fires.

Thermal shock proof : Does not cause cracks to structural elements, steel casings andpower line ceramics, due to the nonexistence of thermal shock damage.

Safe to use : No hazard to humans or damage to property due to low pressure water mist of approx. 150 micron size, generated using plain water.

Maximum efficiency : The mist’s miniscule droplets of water 50 microns cover a larger surface.

Controllable discharge : A simple squeeze grip activation mechanism allows you to control the discharge and optimise use of the extinguishing agent.

EPDM rubber hosepipe : Superior grade EPDM rubber is far more flexible than the normal rubber used in most hosepipes. It is also far less prone to cracks.

World class quality : Comes with ISO 9001 and CE certification, and conforms to ISI standards. Comprehensive Helium Tests and Leak Tests also guarantee that the products you buy are manufactured according to the world’s most stringent quality standards.

6 Year Warranty : The 6 Year Warranty means Ceasefire is looking out for the health of your fire safety products.

Effective usage of water : 95% less water than traditional sprinkler systems with equivalent or better performance.

State of the art pressure gauge : The world’s smallest and yet remarkably easy to read, this is the only pressure gauge that can be tested onsite, using a special magnet to ensure that it is working perfectly and is 100% accurate.

Technical Specification

| Details | 10 Litres | 50 Litres |

|---|---|---|

| Capacity (size) | 10 Ltrs. (As per EN 3-7 :2004+A1:2007) | 50 Ltrs. (As per EN 1866-1:2007-08) |

| Working Pressure | 31 Bar | 31 Bar |

| Water Cylinder – construction | Aluminum Alloy | Aluminum Alloy |

| Back Pack Harness | The harness system is made out of synthetic fire resistant material confirming to IS 15758(Part4) and provides minimum stress and fatigue to the wearer thanks to its ergonomical design. | N/A |

| Air Bottle | 2 liters/200 bar of Mild Steel with PESO Approval and EN Certified Pressure Gauge | 6 liters/300 bar of Mild Steel with PESO approval and EN Approved Pressure Gauge |

| Total weight | 25.65 Kg Max | 106 Kg Max |

| Operating – temperature | Minimum +5 to maximum +60 Celsius | Minimum +5 to maximum +60 Celsius |

| Gun – construction | Stainless Steel Body weighing 814 Gms +- 2 Gms | Stainless Steel Body weighing 814 Gms +- 2 Gms |

| Hose Length | Minimum 1.3 Meter | Minimum 5 Meter |

| Jet – Lancing Distance | 13.2 meters. | 16 meters or more. |

| Jet – Maximum Discharge duration Continuous and at full throttle | 40 to 42 seconds | 120 Seconds |

| Fire extinction – suitability with standard AFFF 6% confirming to IS 4989 or UL 162 standards | Class – A Fires: 55A Class – B Fires: 233B Class – B Polar Solvent Fires Live Electrical fires – 1000 V as per EN 3-7:2004+ A1:2007 Tested for 35 kV Certified by ERDA | Class – A Fires : 55A Class – B Fires: IVB Class – B Polar Solvent Fires Live Electrical fires – 1000 V as per EN 3-7:2004+A1:2007 Tested for 35 kV Certified by ERDA |

| Product Certificates: | Certification from NABL accredited Lab and/ or any Central Govt. Lab. (tested in Indian condition) as per EN 3-7:2004+A1:2007 (tested within last 36 months). Test report shall be enclosed along with the offer. | Certification from NABL accredited Lab and/ or any Central Govt. Lab. (tested in Indian condition) as per EN 1866-1:2007-08 (tested within last 36 months). Test report shall be enclosed along with the offer. |

* Technical specifications are subject to change with time due to our continuous product improvisation initiatives.

Application Areas

- Oil & Petrochemical Factories

- Residential Buildings

- Large Institutions

- Workshops

- Generator Rooms

Reviews

There are no reviews yet.